Zoller+Fröhlich

2D and 3D laser scanners - laser scanning software - laser scanner accessories

Zoller+Fröhlich

2D and 3D laser scanners - laser scanning software - laser scanner accessories

Products

Z+F FlexScan, Mobile Mapping SLAM platform

PRODUCT DETAILS

Highly accurate measurement results require static scans from multiple angles, whereas mobile solutions focus on efficiency. The Z+F FlexScan® platform developed by Zoller + Fröhlich combines the advantages of static scans with the efficiency of mobile systems. The perfect complement for any time-sensitive or large-scale application: AEC, facilitiy management, process industries, heritage documentation and forensics.

Key Functionalities:

- Universal mounting

- Camera system

- Project efficiency

- Easy data collection

- blue workflow®

- Measurement accuracy for the highest demands

Z+F IMAGER® 5016A, 3D laser scanner

PRODUCT DETAILS

The terrestrial 3D laser scanner Z+F IMAGER® 5016A combines compact and lightweight design with state-of-the-art 3D laser scanning surveyor technology - allowing the user to reach new levels. It's equipped with an integrated HDR camera, internal lighting and positioning system. All components of the terrestrial 3D laser scanner have been further developed and adjusted to the new design, resulting in even better scanning results and a more efficient workflow. With feature A, which stands for Advanced, the 5016 receives twice as high scan rate of up to 2.187 million pixels/second and more options for leveling the scanner. If the dynamic compensator is deactivated or the tilt is outside the defined range, the tilt is detected by the IMU of the Z+F IMAGER® 5016A.

Z+F IMAGER® 5016, 3D Laserscanner

PRODUCT DETAILS

The terrestrial 3D laser scanner Z+F IMAGER® 5016 combines compact and lightweight design with state-of-the-art 3D laser scanning surveyor technology - allowing the user to reach new levels. It's equipped with an integrated HDR camera, nternal lighting and positioning system. All components of the terrestrial 3D laser scanner have been further developed and adjusted to the new design, resulting in even better scanning results and a more efficient workflow.

Technical features of the terrestrial 3D laser scanner

Due to innovative developments, the maximum range of the new terrestrial 3D laser scanner Z+F IMAGER® 5016 has been extended to up to 360 m (1,180 ft) - thus establishing new opportunities and applications. The maximum measurement rate of more than 1 Mio. points/sec. guarantees highly accurate results even with long distances.

Its 360° x 320° field-of-view assures great coverage of the scanned area, reducing the number of scan positions necessary to a minimum.

The scanner is classified as „eye-safe“ according to laser class 1 and can therefore be used in public areas without any restrictions.

The terrestrial laser scanner Z+F IMAGER® 5016 is equipped with an integrated positioning system, which allows the automatic registration in the field, with or without targets. All preprocessing tasks can be taken care on the fly, increasing efficiency. Please read the ”real-time registration” section of this brochure for more information. In addition, the scanner comes with an integrated HDR camera, which allows the user to quickly capture colour information - even in challenging lighting conditions.

Z+F IMAGER® 5006EX,

explosion-proof 3D laser scanner

PRODUCT DETAILS

Based on the high quality laser scanner Z+F IMAGER®, Zoller + Fröhlich GmbH and DMT GmbH & Co. KG have developed an explosion proof 3D laser scanner. The Z+F IMAGER® 5006EX pioneers surveying in underground mining and industries where explosive atmospheres occur. The Z+F IMAGER® 5006EX is the world´s first ATEX approved 3D laser scanner for use in mining and industrial applications under explosive conditions. The Z+F IMAGER® 5006EX is class I and class II approved according to ATEX directive 94 / 9 / EG. The ATEX directive 94 /9 / EG "Equipment and protective systems intended for use in potentially explosive atmospheres" is a European standard. The ATEX approval for this equipment is widely accepted outside the European community as well.

Features:

- The laser scanner has a nominal range of 79 m. This range of distances makes it possible to use the scanner efficiently in almost all explosive applications.

- The field of view of 310° vertical and 360° horizontal covers a very large scan area, which enables complete documentation with relatively few scan positions.

- The stand-alone concept guarantees more flexibility. No external equipment is required to scan in the field. Because of that, additional ignition sources in explosive atmospheres are excluded.

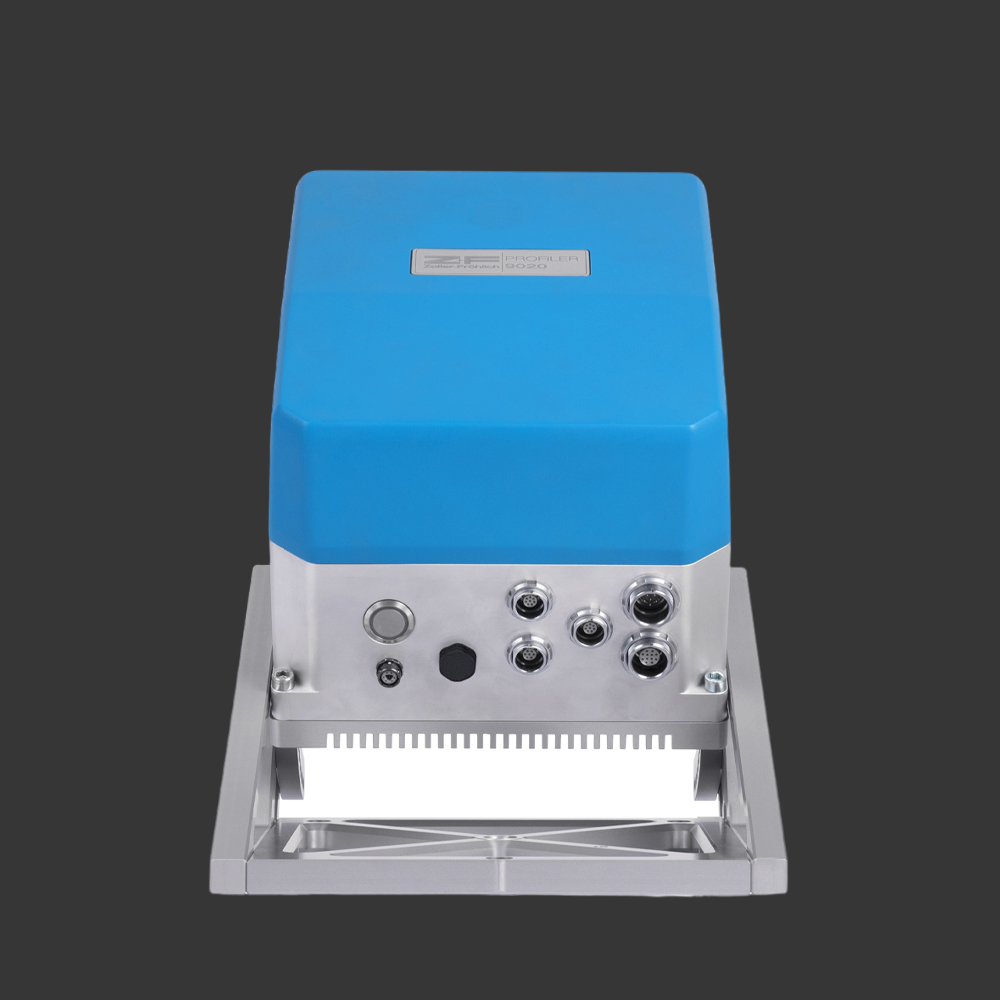

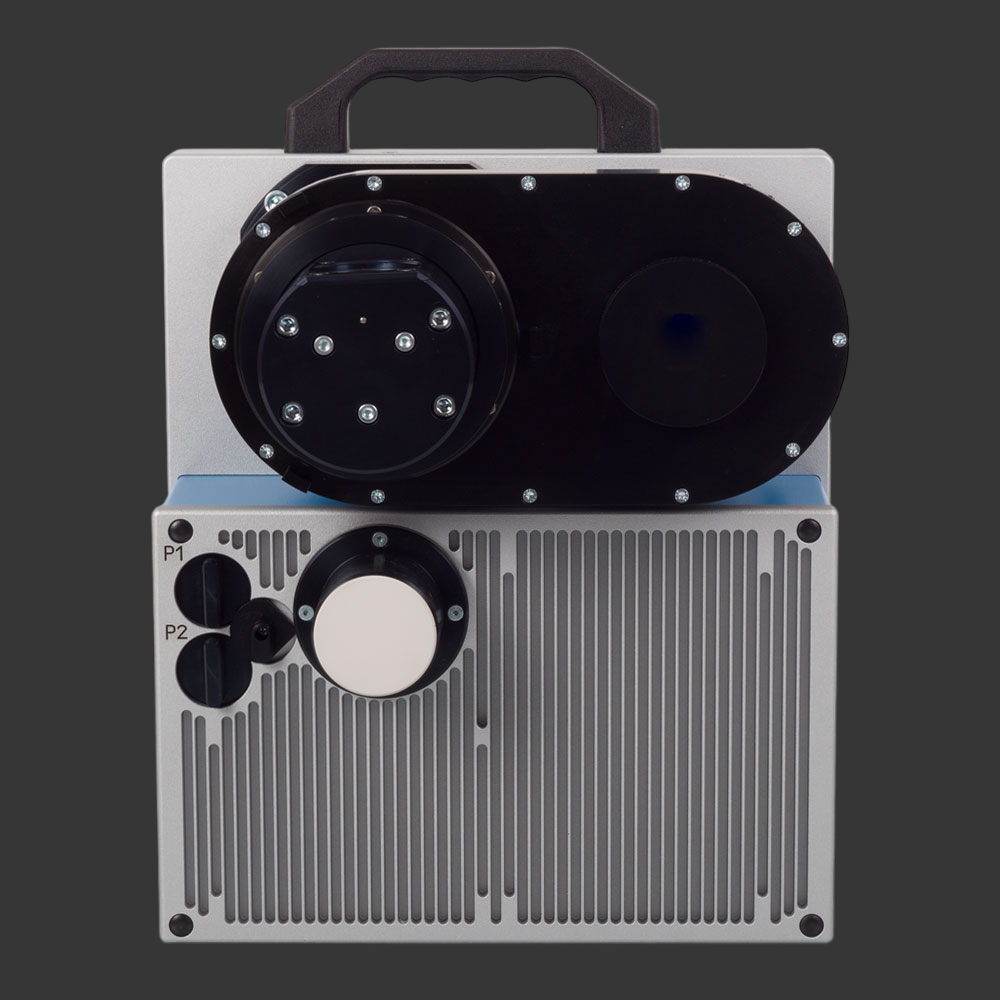

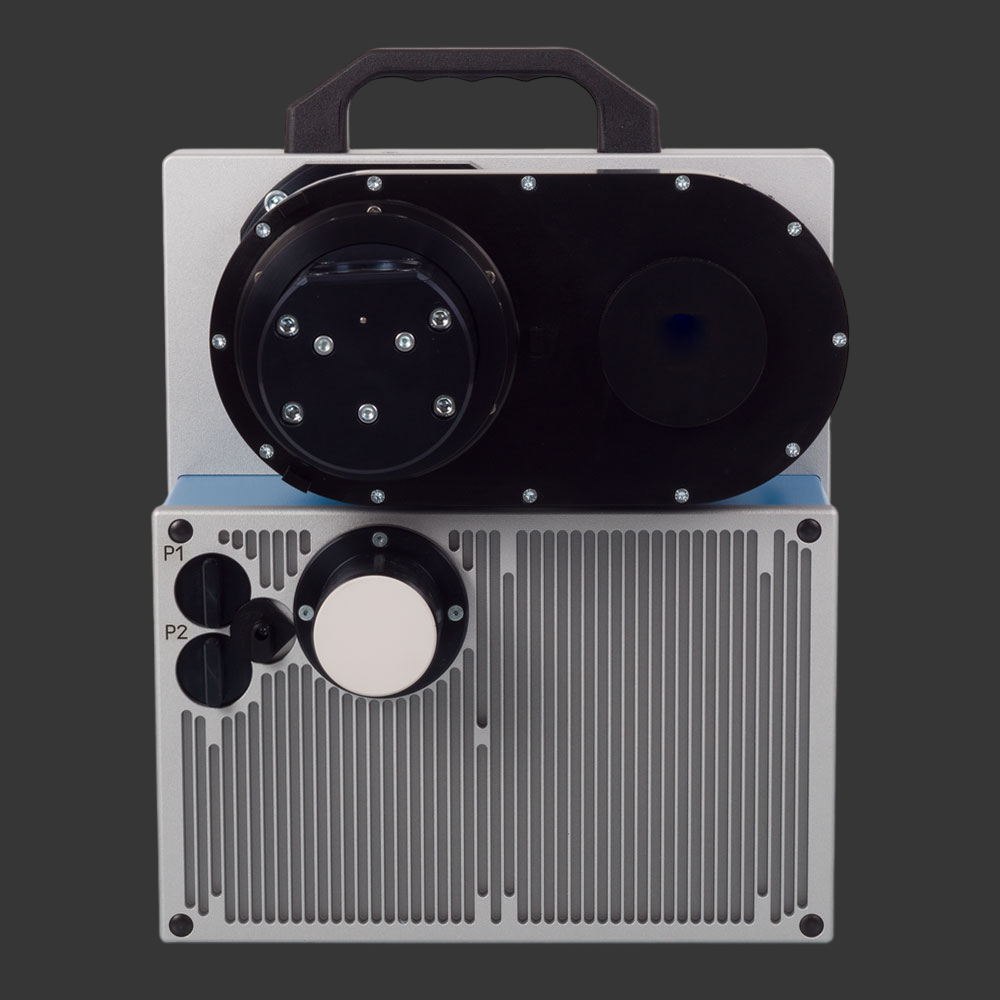

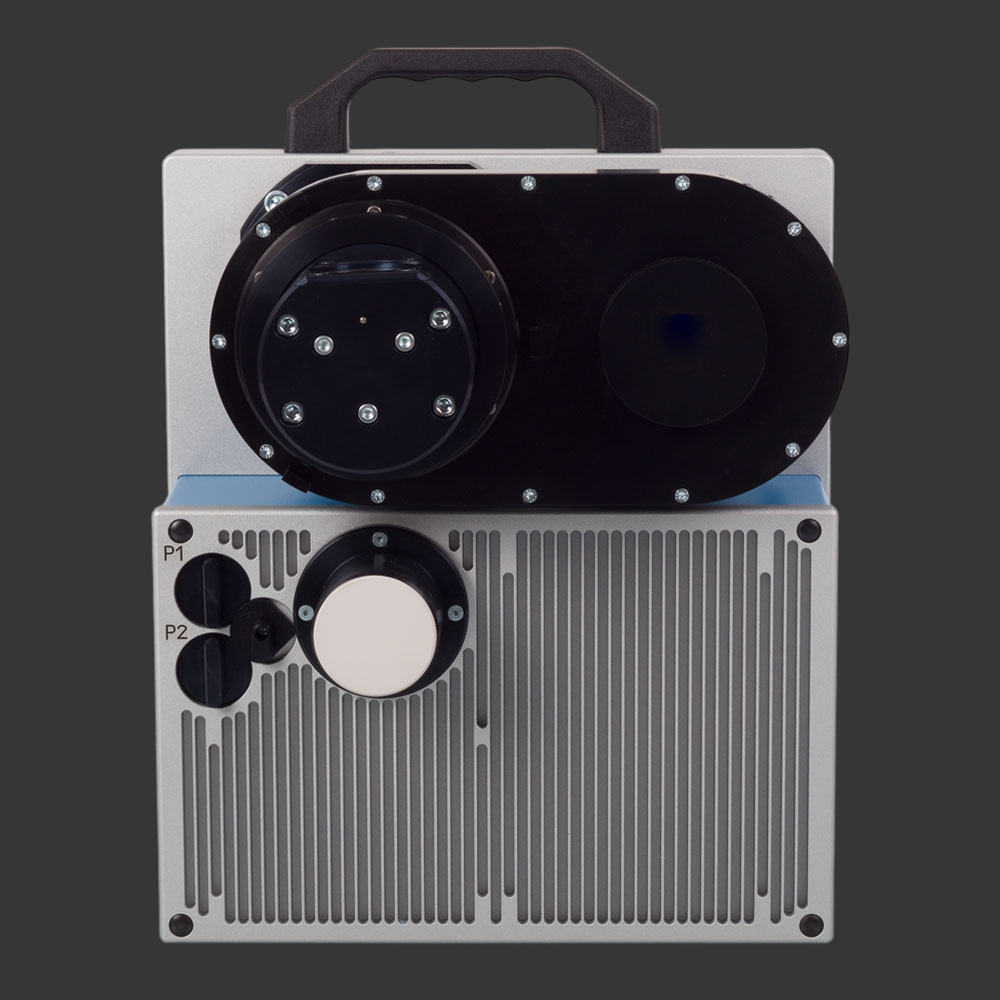

Z+F PROFILER® 9020C, 2D laser scanner

PRODUCT DETAILS

The Z+F PROFILER® 9020C is the world's first mobile 2D laser scanner with integrated cameras.

The P9020C has four integrated cameras, each with 5 MPx, which cover the entire 360° scanning area as of a distance of 40 cm. The recordings have high color fidelity and a high dynamic range. Significant differences in light conditions are compensated in such a way that the processing of the images afterwards takes short time or is completely eliminated. Shaded or overexposed areas can hardly be seen in the colored 3D representations.

The P9020C's built-in cameras allow for quick installation. Only a USB 3 cable is required for the transmission and control of the system components. Fewer cables also mean less susceptibility to errors and, conversely, more security when collecting data. In addition to this efficiency and data security, a high degree of flexibility was taken into account during development. The construction of the P9020C corresponds to that of the P9020. This means that the scanners can be exchanged in just a few minutes, depending on their area of application.

In contrast to external cameras, the permanently installed cameras of the P9020C do not need to be calibrated. The cameras and the scanner are perfectly matched and ready to use upon delivery. The components are also synchronized fully automatically during installation, so that the image and measurement points match exactly. The high accuracy and the low parallax are further optimized by the compact design.

Technical highlights:

- 4 integrated cameras

- Fully calibrated system

- 267 profiles/sec.

- 2 million pixels/sec.

- Accurate to 0.2mm

- 182 m range

- 360° field of view

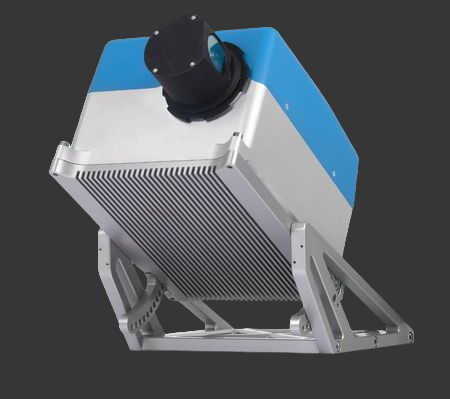

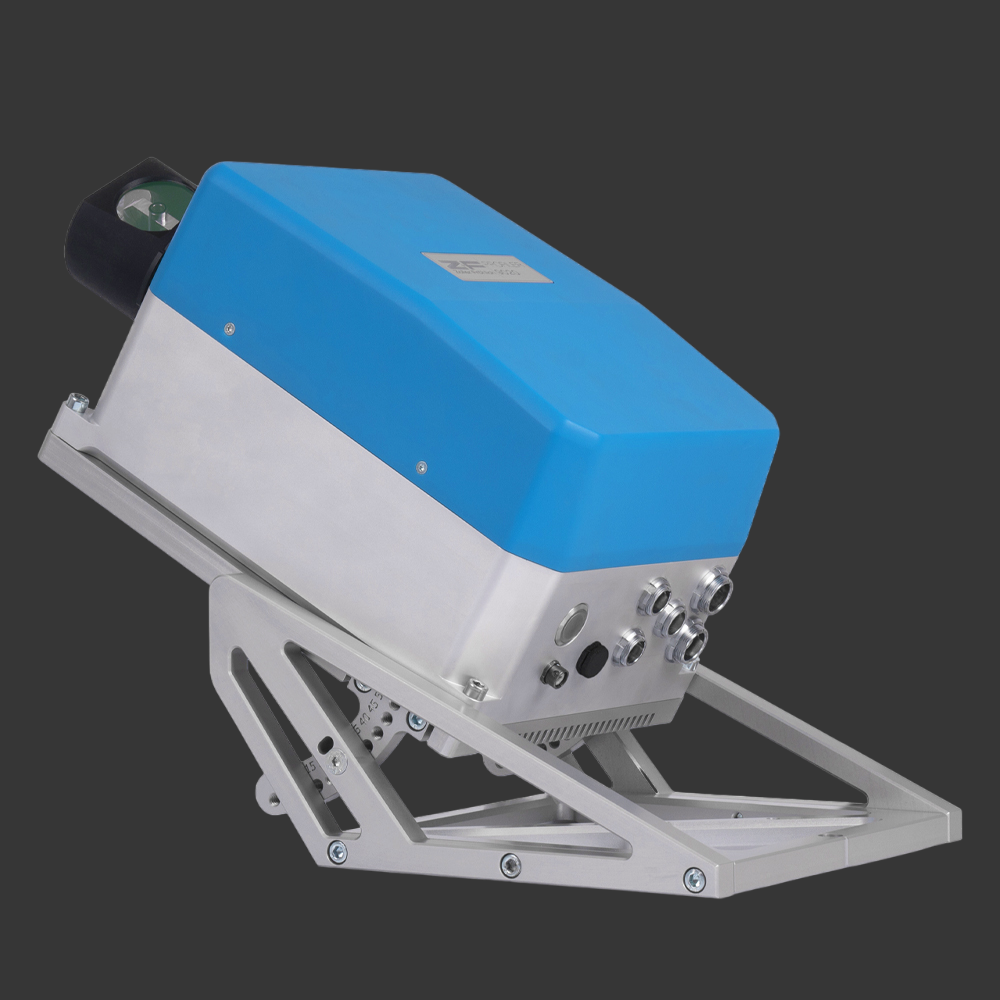

Z+F PROFILER® 9020 | 9020-2, 2D laser scanner

PRODUCT DETAILS

The Z+F PROFILER® 9020 and 9020-2 is a highly efficient 2D laser scanner for mobile mapping applications.

The rotation speed of the Z+F PROFILER® 9020 is 267 Hz or 16,020 rpm max.

It measures up to 182 m and has a very high data quality. For data capturing in close range,

it is equipped with special optics. Compared to previous models, it has an internal reference plate,

a very low power consumption, very fast startup time and over 50% reduced weight and size.

A new, very powerful laser technology and further developed algorithms ensures highly accurate measurement

results on rails, roads, street signs and other traffic control systems such as traffic lights.

Technical highlights:

- 267 profiles/sec.

- P9020: 1.094 million points/sec.

- P9020-2: 2.188 million points/sec.

- 0.2 mm accuracy

- 182 m range

- 360° field of view

The Z+F PROFILER® 9020 and 9020-2 can be flexibly integrated into different MMS. The Z+F PROFILER® 9020 has several ports for fast and free from interference communication between the components like Z+F MapCam®, GNSS receiver and operator PC.

Z+F PROFILER® 9012, 2D laser scanner

PRODUCT DETAILS

The Z+F PROFILER® 9012 has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software.

Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction.

A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

Features:

- The Z + F PROFILER® 9012 has a rotation speed of 200 rps (profiles /sec) and measures over 1 million points / sec

- With a maximum range of 119 m, the profiling scanner is suitable for almost all mobile mapping applications

- The Z + F PROFILER® 9012 is dust and splash-proof with protection class IP 54 and can be used at temperatures between -10 and +45 ° C. Additionally laser class 1 allows use in urban environments

Z+F PROFILER® 9012 A, 2D laser scanner

PRODUCT DETAILS

The Z+F PROFILER® 9012 A has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software.

Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction.

A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

The Z+F PROFILER® 9012A is the optimal 2D laser scanner for close range applications due to its optimized range noise within 1 – 5 m.

The Z+F PROFILER® is also available as a Z+F PROFILER® 9012 MA model, which combines the marker mode and close range high precision surveying.

Features:

- The Z+F PROFILER® 9012 A has a rotation speed of 200 rps (profiles /sec) and measures over 1 million points / sec

- With a maximum range of 119 m, the profiling scanner is suitable for almost all mobile mapping applications

- The Z+F PROFILER® 9012 A is dust and splash-proof with protection class IP 54 and can be used at temperatures between -10 and +45 ° C. Additionally laser class 1 allows use in urban environments

Z+F PROFILER® 9012 M, 2D laser scanner

PRODUCT DETAILS

The Z+F PROFILER® 9012 M has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software. Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction.A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

Features:

- The Z+F PROFILER® 9012 M has a rotation speed of 200 rps (profiles /sec) and measures over 1 million points / sec

- With a maximum range of 119 m, the profiling scanner is suitable for almost all mobile mapping applications

- The Z+F PROFILER® 9012 M is dust and splash-proof with protection class IP 54 and can be used at temperatures between -10 and +45 ° C. Additionally laser class 1 allows use in urban environments

Z+F LaserControl®, Laserscanning software

PRODUCT DETAILS

Z+F LaserControl® Office and Scout are the optimal solution to work efficiently and fully with the laser scanners of Zoller + Fröhlich. A range of filters, measurement and registration tools enable a high differentiate processing of scan data and are the key to filter, register and color 3D point clouds. Thanks to the large selection of export formats provided by Z+F LaserControl®, data can be imported and further processed in all common 3D software applications.

blue workflow®

The blue workflow® describes a series of optimized work steps for measuring and processing measured data. The focus is on flexibility, data security and efficiency. With Z+F LaserControl® Scout and the laser scanners Z+F IMAGER® 5010X and 5016, point clouds can be registered, checked, processed and evaluated in real time in the field.

In addition, the user immediately recognizes problems in the project through immediate visualization and can intervene directly on site.

In detail, the blue workflow® allows the users to carry out the following work steps in the field:

- Registration of the point clouds

- Check the scanned targets

- Verification of data quality and quantity

- Direct integration of handheld scanner data

Multi-scanner feature

With the new blue workflow®, several scanners can be used simultaneously in one project.

With the multi-scanner principle, all scanners work on the same project file and synchronize with a Windows tablet.

Office-Link

The new module provides project planning tools and establishes direct communication and a feedback loop between field and office.

During the planning stage, the project coordinator can start with an empty project, loading in groundplans or aerial photography and can enrich the project plan with annotations, images, documents and audio recordings. Also tasks can be defined and assigned to the individual field teams. In addition, it is possible to plan scan positions to get an overview about the total duration of the project.

During a project, all data, including scans and images can be exchanged via an FTP server or cloud-folders (e.g. Dropbox). This allows providing a status report to the supervisors back at the office, who can also comment and send feedback back to the field. It is also possible to start the processing of the partial data in the office, while the team is still out in the field acquiring more scans.

The Office Link module and features are available to all Z+F LaserControl® Office and Scout packages, including Z+F LaserControl® Office Elements.

Z+F SynCaT®, Mobile Mapping Software

With the software Z+F SynCaT®, Zoller+Fröhlich creates a connection between the Z+F PROFILER® 9012 and external positioning and navigation systems. SynCaT stands for synchronization, calibration and transformation - also representing the main tasks of the software. Z+F SynCat® includes all the features below:

Calibration: Processing of calibration parameters due to different system integrations (translation, rotation offsets between the coordinate systems of the navigation-unit (trajectory) and the Z+F PROFILER® 9012 laser scanner)

Synchronization: Synchronize Z+F PROFILER® 9012 laser scanner data with trajectory data and generate 3D point cloud files

Transformation: Transform 3D point cloud data to different local coordinate systems and apply different local/global height correction models (geoid correction files)

Correction: Individual offset estimation referring to predefined ground control points (GCP’s)

Z+F SynCaT® is a modular structured mobile mapping software. The modularization allows to combine the software package specifically for the customer needs.

AVEVA LFM

LFM Modeller

With LFM Modeller, users can create intelligent 3D models of existing laser scan data and export the models to a variety of 3D CAD systems, with some few clicks.

LFM NetView

LFM NetView is a web-based application suitable for engineering and asset management. The application is available either as a standalone application or as a web browser plug-in, allowing free, secure access to huge databases with an unlimited number of scans.

LFM Server

With LFM Server, users can access and work with pre-registered 3D laser scan data, compare the planned design with existing data, and use CAD packages from AVEVA, Autodesk, Bentley, or Intergraph.

LFM Gateway

LFM Gateway provides a unique connection to terrestrial 3D scanners. The application can import data from mobile, handheld or airborne laser scanning.

Clear Edge - EdgeWise®

Structure Modeling Tools

Reduce Modelling Time by Up to 80% with the Automated Structural Modeling Tools in EdgeWise 5.1.

The speed and accuracy of EdgeWise automated feature extraction — now for structural steel and concrete.

Modelling steel from scan data can be a pain. Current software is slow and often inaccurate, leading to missed deadlines and cost overruns. The new structural modeling tools in EdgeWise 5.0 change all that by applying advanced extraction algorithms and automated modeling technologies to accurately extract steel, concrete and wood structure faster than ever before.

Plant Modeling Capabilities

EdgeWise offers a host of features and tools to bring you from field-to-finish more accurately and much faster than ever before. Automated extraction, spec-driven fitting placement, billion-point visualization, and exacting quality assurance tools all combine to make EdgeWise a true end-to-end modeling solution for process plants. And now, EdgeWise is fully integrated with Plant 3D, PDMS and PCF so the intelligent models you create in EdgeWise Plant can be exported to nearly all plant design platforms with no loss of data.

MEP Modeling Capabilities

For the first time, users can import 3D MEP models directly into Revit as Revit Family objects. Through this deep integration, EdgeWise users can practically eliminate the need for manual MEP modeling of pipes, conduit and round ducting in Revit.

EdgeWise Building Modeling Tools

EdgeWise uses groundbreaking algorithms that can automatically identify and extract walls and windows from point clouds and export them as Revit family objects. You’ll save countless hours over creating as-built BIMs natively in Revit.

JRC 3D Reconstructor®

THE POWERFUL PROCESSING SOFTWARE FOR LIDAR DATA

Import, process and manage your LiDAR data from terrestrial, handheld, mobile, airborne laser scanners and easily integrate UAV and 3D imaging data in a single platform. Thanks to the LineUp® Pro technology, automatically align your 3D scans, even without targets!

- Import point clouds, meshes, CAD models

- Automatic alignment also without targets

- Post-processing, analysis and output export

Scantra® - Beyond clouds

Scantra® is a programme for automated registration of point clouds captured by terrestrial laser scanners based on identical planes and points. It has been designed to process very large projects with hundreds to thousands of scans with superior accuracy way beyond the error-budget of ICP-based solutions. Typical fields of application are as-built documentation, construction site monitoring or deformation measurement. Scantra is the only software on the market that satisfies established demands from Geodetic Engineering by delivering extensive and meaningful quality measures which stem from a high-performance Block Adjustment. Scantra is capable to handle highly redundant registrations as a consequence of loop-closure constraints yielding in reliable results.]

Be a part of our net - your advantages at a glance:

- Efficiency - Reduced time on site by omitting targets

- Precision - Enhanced error budget by use of planes (instead of points)

- Performance - Process several thousand scans on standard hardware

- Transparency - Sound reports for quality assurance based on a block adjustment

Z+F MapCam® S, laserscanning accessory

PRODUCT DETAILS

With the camera system of Zoller + Fröhlich, color information can be mapped into data measured by the Z+F PROFILER® 9012 in one step.

The camera system Z+F MapCam S has high-resolution sensors, a very wide field of view and covers the entire measuring area.

The high frame rate of the cameras allows gapless and sharp images at speeds of up to 80 km/h.

The camera system is easy to install with just one tool. In addition, it may be used with any mobile mapping system (MMS) which is compatible with the Z+F PROFILER® 9012.

Z+F MapCam® S+

The new camera system Z+F MapCam® S+ has high-resolution sensors, a very wide field of view and a high dynamic range with images. Combined with the MapCams they cover the whole measuring area of the 2D laser scanner.

The camera S+ is exactly matched to the basic camera C , fully compatible with them and provide very realistic and parallax-free color information.

Z+F MapCam® C, laserscanning accessory

PRODUCT DETAILS

With the camera system of Zoller + Fröhlich, color information can be mapped into data measured by the Z+F PROFILER® 9012 in one step.

The camera system Z+F MapCam C has high-resolution sensors, a very wide field of view and covers the entire measuring area.

The high frame rate of the cameras allows gapless and sharp images at speeds of up to 90 km/h.

The camera system is easy to install with just one tool. In addition, it may be used with any mobile mapping system (MMS) which is compatible with the Z+F PROFILER® 9012.

Z+F MapCam® C+

The new camera system Z+F MapCam® C+ has high-resolution sensors, a very wide field of view and a high dynamic range with images. Combined with the MapCams they cover the whole measuring area of the 2D laser scanner.

The camera C+ is exactly matched to the basic camera C , fully compatible with them and provide very realistic and parallax-free color information.

Z+F T-Cam, laserscanning accessory

The infrared camera Z+F T-Cam is an external solution to document rooms and objects not only three-dimensionally but also thermally. The camera generates 360° thermal panoramas with a resolution of 382x288 pixels. The infrared information is automatically being mapped onto the point cloud. The infrared spectral range is from 7.5 - 13 μm. By using the Z+F T-Cam, many new opportunities arise in the fields of insurance, facility management, industry and forensics. The T-Cam is easy to mount and is connected to the scanner via USB.